Where are straightening rollers used?

Metal processing plants are surely the main usage scenario, such as steel mills, aluminum processing plants, etc.. In these places, straightening rolls are mounted on straightening machines to handle various metal materials. In addition, straightening rolls are also used in automobile manufacturing, as body parts require high-precision sheet metal. There is also the handling of high-strength materials in mechanical engineering, the construction industry (e.g. steel structures), pipe production (e.g. water and oil pipes), and in aerospace.

Straightening rolls are mainly used in the field of metal processing, and the common use scenarios include:

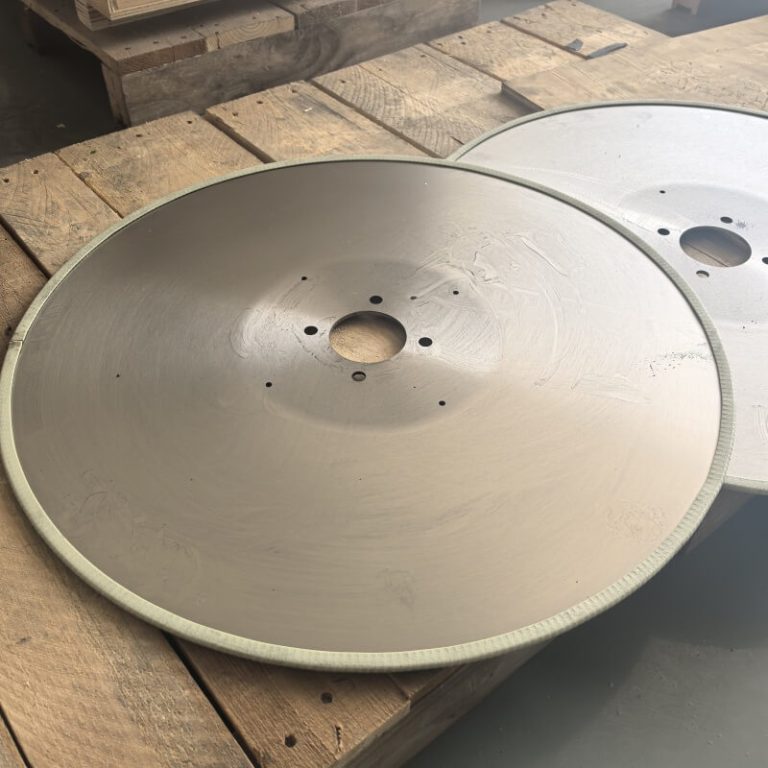

1. **Rolling production line**: for continuous straightening of steel plates, aluminum plates and other metal sheets

2. **Pipe processing**: straightening the straightness of tubular materials such as steel pipe, copper pipe, etc.

3. **Profile production**: straightening of construction profiles such as H-beams, angles, etc.

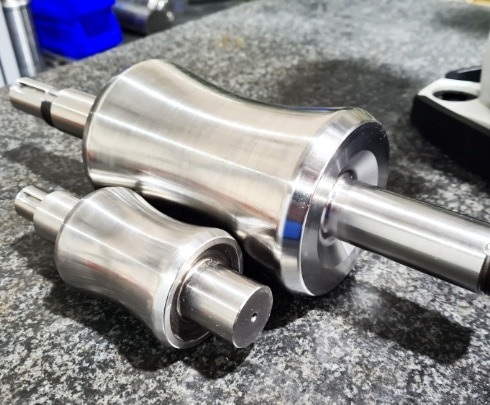

4. **Automobile manufacturing**: precision straightening of body sheet metal parts, transmission shafts and other components

5. **Machining**: Straightness correction of shaft parts, guide rails and other mechanical parts.

Its core role is to eliminate the bending deformation of the material in the processing/heat treatment process, to ensure that the product meets the specified straightness requirements (usually the precision control ranges from 0.1-3mm/m). Different industries will choose the corresponding roll structure and arrangement according to the material thickness (0.5-300mm) and strength (200-2000MPa).