Roller Straightening Machines in Modern Manufacturing Industries

Roller straightening machines, also known as leveling machines or roll straighteners, are indispensable pieces of equipment in modern manufacturing industries, especially those dealing with metalworking. These machines play a crucial role in improving the quality of metal products by eliminating internal stresses, correcting deformations, and ensuring dimensional accuracy. This press release provides a comprehensive overview of roller straightening machines, covering their working principles, types, applications, advantages, and future trends.

Working Principles

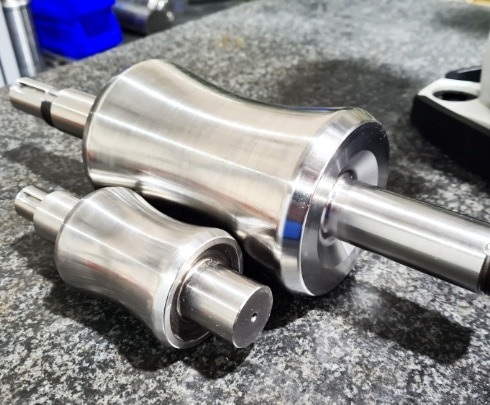

The core operation of a roller straightening machine is based on the principle of plastic deformation. When a deformed or stressed metal strip, bar, or tube passes through a series of strategically arranged rollers, it undergoes controlled bending and unbending. This process applies alternating stresses to the material, gradually evening out the internal stress distribution and straightening the workpiece.

The rollers are typically arranged in an alternating upper and lower configuration, forming a “S” or “Z” – shaped path for the material. As the metal piece moves through the rollers, each roller pair applies a specific amount of bending force, gradually reducing the curvature or twist. The number of rollers, their diameter, spacing, and the pressure exerted are all adjustable parameters, allowing for precise control over the straightening process based on the material’s properties and the degree of deformation.

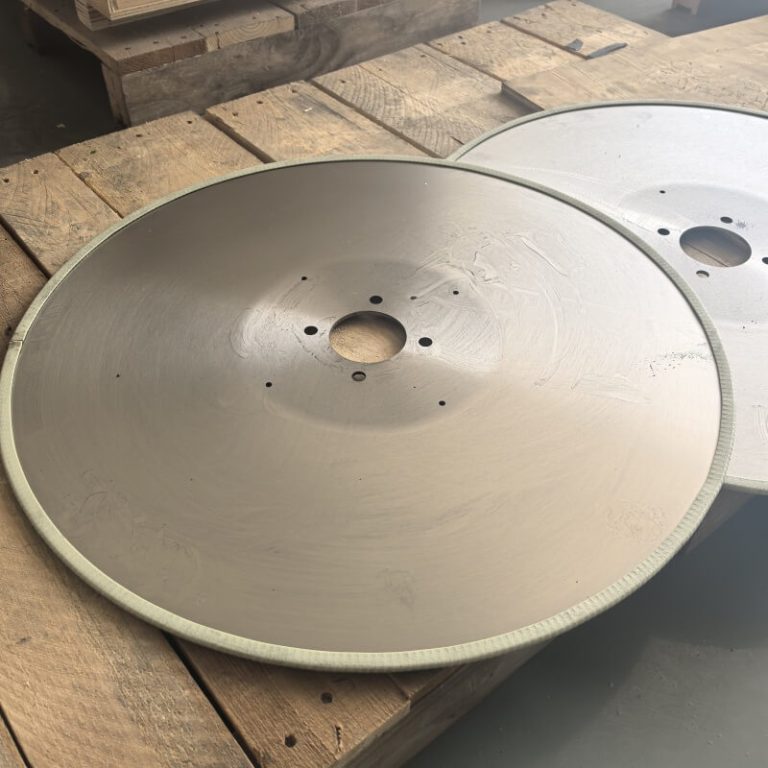

Types of Roller Straightening Machines

1. Two – Roll Straightening Machines

These are relatively simple in design and are often used for straightening thin strips or wires. They apply a basic bending force to correct minor deformations.

2. Multi – Roll Straightening Machines

With a larger number of rollers, usually ranging from five to twenty – one or more, these machines can handle a wider range of materials, including thick bars, tubes, and complex – shaped profiles. The increased number of rollers allows for more precise and gradual straightening, reducing the risk of material damage.

3. Rotary Straightening Machines: In this type, the workpiece rotates while passing through the rollers. It is particularly useful for straightening long tubes or rods, providing uniform straightening along the entire length.

Applications

1. Automotive Industry:

Roller straightening machines are extensively used in the production of automotive components such as chassis frames, suspension parts, and engine shafts. Precise straightening ensures proper assembly and performance of these critical parts.

2. Construction Sector:

For manufacturing steel beams, pipes, and rebars used in building construction, straightening is essential to meet structural integrity requirements. Roller straightening helps eliminate any bending or twisting that could compromise the strength of the materials.

3. Aerospace Industry:

In the aerospace field, where high – precision and lightweight materials are crucial, roller straightening machines are used for straightening aircraft landing gear components, turbine blades, and other critical parts. The strict tolerance requirements in aerospace manufacturing make these machines invaluable.

Advantages

1. Improved Product Quality: By eliminating internal stresses and correcting deformations, roller straightening enhances the mechanical properties and dimensional accuracy of the final product, reducing the likelihood of defects during subsequent processing or use.

2. Increased Production Efficiency: Automated roller straightening machines can operate at high speeds, processing a large number of workpieces in a short time. This reduces production cycle times and increases overall output.

3. Cost – Effectiveness: Straightening materials early in the production process can prevent costly rework or scrap later on. It also allows for the use of lower – cost materials that may have initial deformations, as the straightening process can correct them.

Future Trends

As manufacturing technology advances, roller straightening machines are expected to become more intelligent and automated. Integration with sensors and real – time monitoring systems will enable precise control of the straightening process, adjusting parameters on the fly based on material feedback. Additionally, there is a growing demand for machines capable of handling new materials, such as advanced high – strength steels and composite materials, which require specialized straightening techniques.

In conclusion, roller straightening machines are vital production equipment that contribute significantly to the quality, efficiency, and cost – effectiveness of modern manufacturing. With ongoing technological advancements, they will continue to play a pivotal role in shaping the future of various industries.