How to Choose Steel Pipe Production Accessories?

Selecting the right steel pipe production accessories is crucial for ensuring the efficiency, quality, and longevity of your steel pipe manufacturing operations. With a wide range of accessories available in the market, each with its own specifications and features, making an informed decision requires careful consideration of several key factors. Here’s a detailed guide to help you navigate the selection process.

1.Understand Your Production Requirements

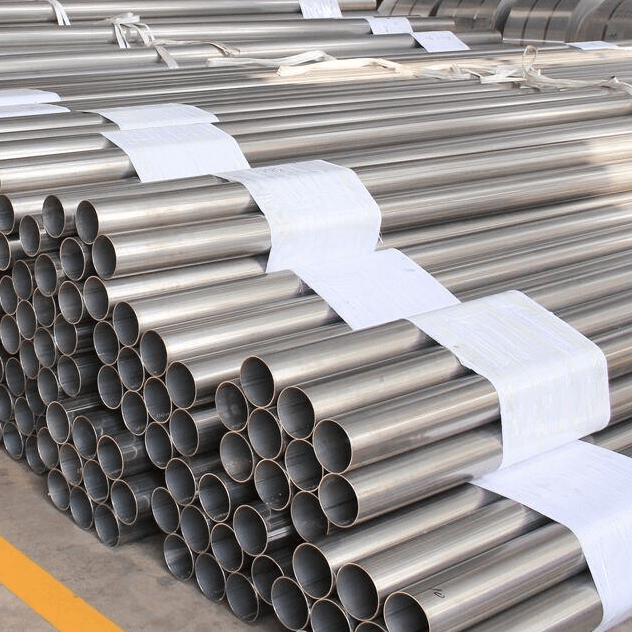

Before diving into the world of steel pipe production accessories, it’s essential to have a clear understanding of your specific production needs. Consider factors such as the type of steel pipes you manufacture (e.g., seamless, welded, ERW), the size range (diameter and wall thickness), the production volume, and the quality standards you need to meet. Different accessories are designed to cater to various production scenarios, so knowing your requirements upfront will narrow down your options and ensure you choose accessories that are perfectly suited for your operations.

2.Quality and Durability

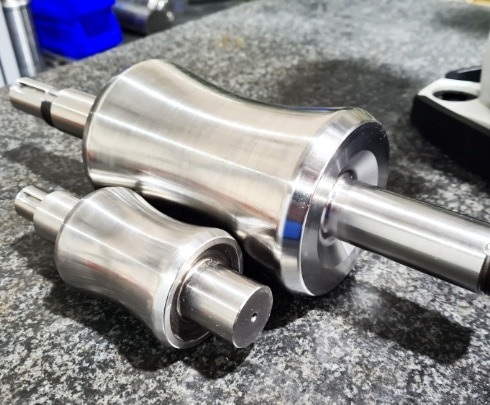

The quality and durability of steel pipe production accessories are of utmost importance. High-quality accessories are built to withstand the rigors of continuous production, reducing the risk of breakdowns, downtime, and costly repairs. When evaluating accessories, look for those made from robust materials that can resist wear, corrosion, and high temperatures. Check for certifications and standards compliance, such as ISO or industry-specific quality marks, which indicate that the accessories have undergone rigorous testing and meet recognized quality benchmarks. Investing in durable accessories may require a higher upfront cost, but it will pay off in the long run through increased reliability and reduced maintenance expenses.

3.Compatibility with Your Machinery

Ensure that the accessories you choose are fully compatible with your existing steel pipe production machinery. This includes checking the dimensions, connections, and operating parameters to guarantee a seamless integration. Incompatible accessories can lead to inefficiencies, poor performance, and even damage to your equipment. Consult with the machinery manufacturer or a knowledgeable supplier to confirm compatibility and get recommendations on the most suitable accessories for your specific machines. Additionally, consider the ease of installation and whether any modifications to your existing setup will be required.

4.Performance and Efficiency

The performance and efficiency of steel pipe production accessories directly impact your overall productivity and cost-effectiveness. Look for accessories that offer high-speed operation, precise control, and consistent results. For example, in the welding process, choose welding accessories that provide stable arcs, proper penetration, and minimal spatter to ensure strong and uniform welds. In the forming and sizing stages, accessories with accurate dimensional control can help you achieve tight tolerances and reduce scrap rates. Evaluate the energy consumption of the accessories as well, as energy-efficient models can significantly lower your operating costs over time.

5.Maintenance and Serviceability

Easy maintenance and good serviceability are essential for keeping your steel pipe production accessories in optimal condition. Opt for accessories that are designed with accessibility in mind, allowing for quick and straightforward maintenance tasks such as cleaning, lubrication, and part replacement. Accessories with readily available spare parts and a reliable service network are also preferable, as this ensures that any issues can be resolved promptly, minimizing downtime. Additionally, consider the maintenance requirements and intervals recommended by the manufacturer, and factor these into your long-term cost calculations.

6.Supplier Reputation and Support

The reputation and support provided by the accessory supplier are as important as the quality of the products themselves. Choose a reputable supplier with a proven track record in the steel pipe production industry. Look for suppliers who offer comprehensive technical support, including training on the use and maintenance of the accessories, troubleshooting assistance, and after-sales service. A reliable supplier will also be able to provide valuable advice on product selection, upgrades, and industry best practices. Check customer reviews and testimonials to gauge the supplier’s reputation and level of customer satisfaction.

7.Cost-Effectiveness

While cost is an important consideration, it should not be the sole determining factor when choosing steel pipe production accessories. Instead, focus on the overall cost-effectiveness, which takes into account the initial purchase price, operating costs, maintenance expenses, and the expected lifespan of the accessories. Sometimes, spending a bit more upfront on a higher-quality accessory can result in significant savings over time due to reduced downtime, lower maintenance costs, and improved product quality. Compare prices from different suppliers, but also consider the value-added services and support they offer.

In conclusion, selecting the right steel pipe production accessories requires a thorough evaluation of your production requirements, quality, compatibility, performance, maintenance needs, supplier reputation, and cost-effectiveness. By taking the time to make an informed decision, you can enhance the efficiency, quality, and profitability of your steel pipe manufacturing operations. Remember to regularly review and update your accessories as technology advances and your production needs evolve to stay competitive in the market. If you’re not sure how to choose steel pipe production accessories, feel free to contact the experts at Shengyuan Machinery to learn more.