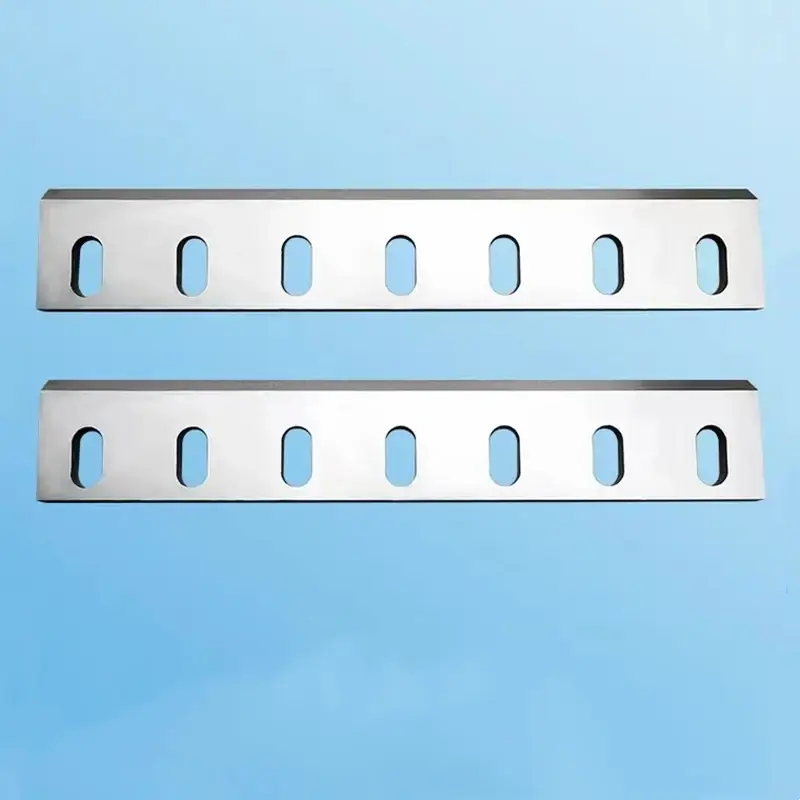

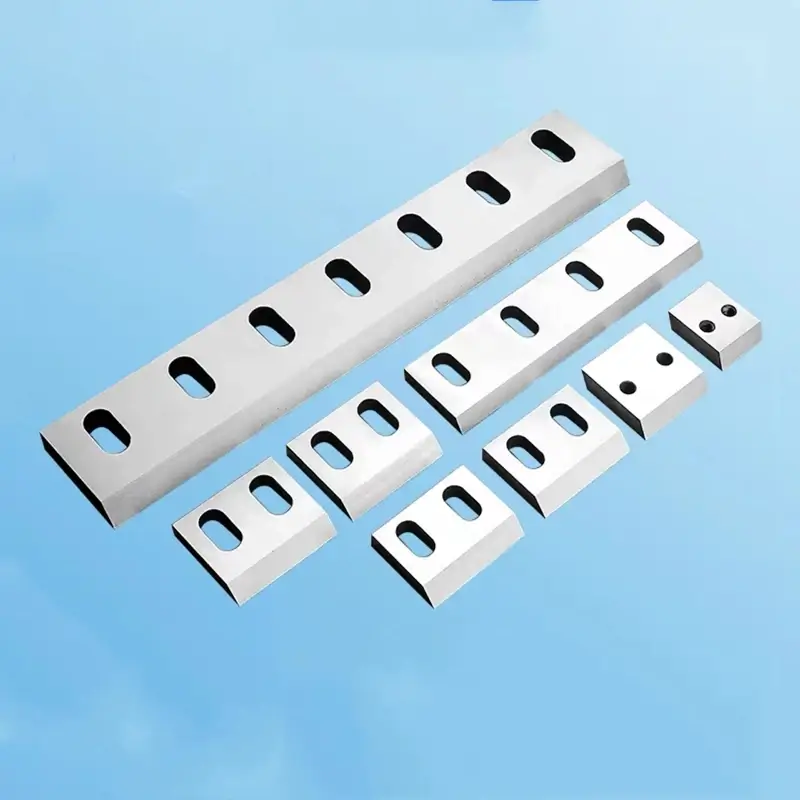

Cutting Machine Knife Versatile Industrial Blade Applications

In the vast realm of industrial machinery and processes, industrial blades play a pivotal role in various industries, from precision manufacturing to heavy-duty construction. These blades are designed to cut, slice, shear, or grind materials with unparalleled efficiency and accuracy. This article delves into the myriad applications of industrial blades, their significance in various industries, and the technological advancements that have propelled their effectiveness.

Overview of Industrial Blades

Industrial blades come in a wide range of shapes, sizes, and materials, each tailored to specific applications. They can be made from high-speed steel (HSS), carbide, ceramics, cubic boron nitride (CBN), or polycrystalline diamond (PCD), depending on the material being cut and the desired level of wear resistance. The design of these blades often incorporates advanced engineering principles to optimize cutting performance, reduce friction, and extend tool life.

Key Industries Utilizing Industrial Blades

1. Manufacturing

In the manufacturing sector, industrial blades are indispensable for processes such as metal cutting, plastic molding, and woodworking. For instance, carbide-tipped saw blades are commonly used in CNC routers for cutting intricate designs in wood, plastics, and composites. Similarly, precision grinding wheels made of CBN or PCD are employed in the automotive industry for finishing engine parts and other high-precision components.

2. Food Processing

The food industry relies heavily on industrial blades for slicing, dicing, and chopping various ingredients. From the high-speed rotary blades used in meat slicers to the sharp knives in vegetable processors, these blades ensure consistent product quality and enhance production efficiency. Additionally, specialized blades designed for use in freezers and cold storage environments prevent product degradation due to heat generation during cutting.

3. Construction and Mining

In the construction and mining industries, industrial blades are crucial for earthmoving, demolition, and material handling. Heavy-duty excavator buckets, bulldozer blades, and road milling machines all utilize specialized blades to efficiently cut through soil, rock, and asphalt. The durability and wear resistance of these blades are paramount in ensuring minimal downtime and maximum productivity in harsh operating conditions.

4. Textile and Leather Processing

The textile and leather industries also make extensive use of industrial blades. In the textile sector, circular knives and slitting blades are employed for cutting fabrics, foils, and films. Leather processors utilize precision skiving knives and embossing blades to achieve the desired texture and thickness in leather products. The sharpness and precision of these blades are critical in maintaining the quality of the final product.

5. Paper and Printing

The paper and printing industries rely on industrial blades for trimming, perforating, and slitting paper rolls. Guillotine cutters and rotary shears are common examples of blades used in these processes. The ability of these blades to handle high-speed cutting with minimal wear and tear is essential in maintaining production speed and reducing waste.

Technological Advancements in Industrial Blades

Recent technological advancements have significantly enhanced the performance and longevity of industrial blades. One such innovation is the development of coated blades, which utilize advanced coatings such as titanium nitride (TiN) or titanium aluminum nitride (TiAlN) to improve wear resistance and reduce friction. These coatings not only extend tool life but also enhance cutting efficiency and surface finish.

Another significant development is the integration of advanced materials like CBN and PCD into blade manufacturing. These materials offer unparalleled hardness and wear resistance, making them ideal for cutting hard and abrasive materials. The use of CBN and PCD blades in the automotive and aerospace industries has revolutionized the way high-precision components are machined.

Furthermore, the advent of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies has enabled the creation of custom-made blades tailored to specific cutting requirements. This level of customization ensures optimal performance and minimizes material waste.

Conclusion

Industrial blades are indispensable tools in a wide array of industries, from precision manufacturing to heavy-duty construction. Their versatility and efficiency have made them critical components in various production processes. With continuous advancements in materials science, coating technologies, and manufacturing processes, the performance and longevity of these blades are set to improve even further. As industries continue to evolve, so too will the role and importance of industrial blades in shaping the future of manufacturing and processing.