Carbide blade

High hardness, wear resistance and heat resistance. The hardness remains unchanged at 500℃ and still has high hardness at 1000℃. It is suitable for multi-material processing.

Showing 1–12 of 13 results

High hardness, wear resistance and heat resistance. The hardness remains unchanged at 500℃ and still has high hardness at 1000℃. It is suitable for multi-material processing.

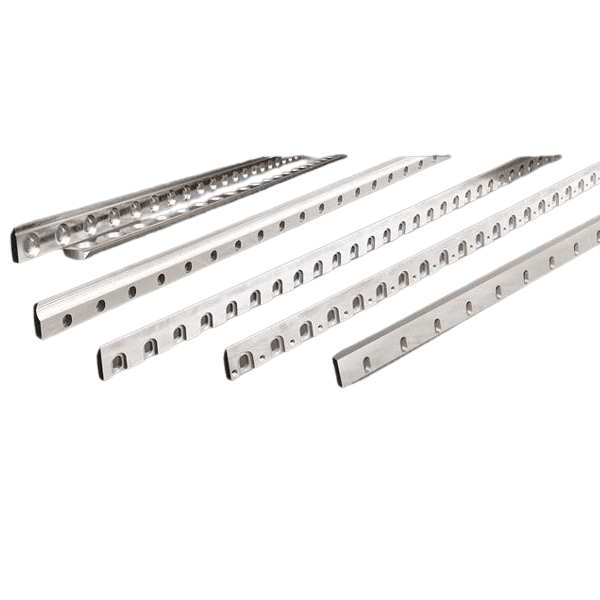

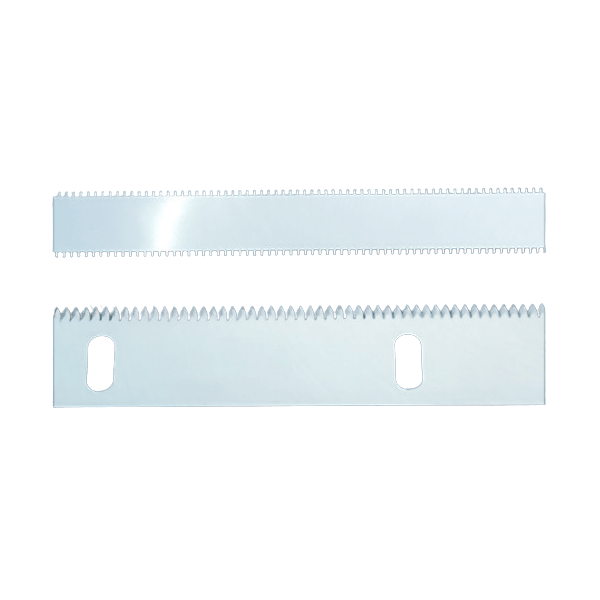

Material: tool steel, carbide Features: sharp, wear-resistant Purpose: Carton production and slitting

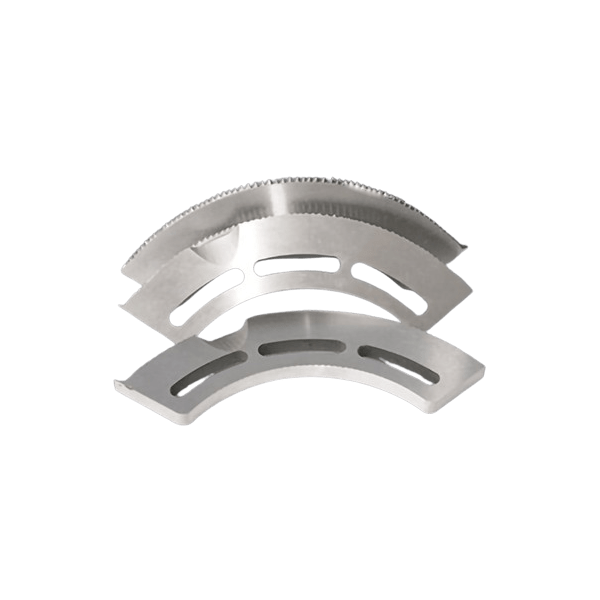

Rotary cutting knife design Easy to thread paper, no paper replacement equipment required Save cost and space, easy to adjust the cutting length

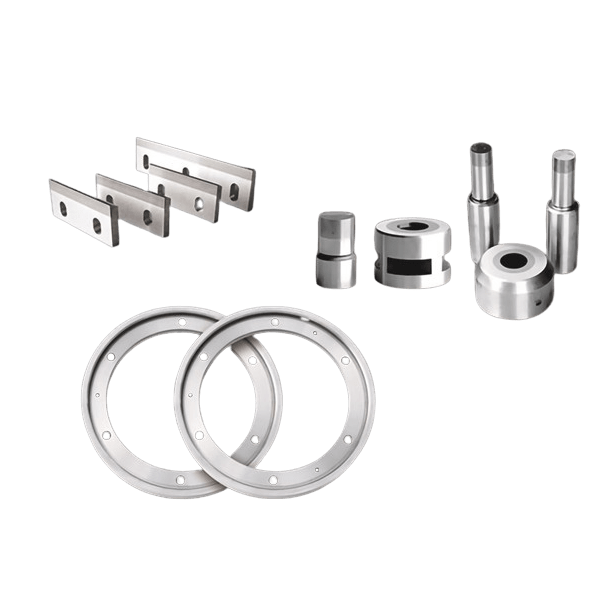

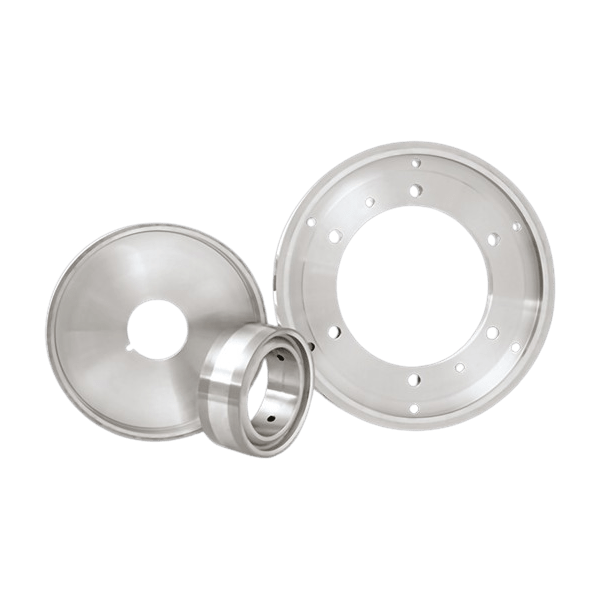

Common tools for mold processing Disc, rectangular, round and other types Cut off metal blanks or excess to ensure precise cuts

High hardness: 60-65HRC, strong wear resistance. High temperature resistance and good toughness. The knife edge is sharp and durable, with superior performance.

Motor driven, convenient for inner wall grooving High speed steel or carbide material Suitable for metal processing to improve the strength of expanded tubes

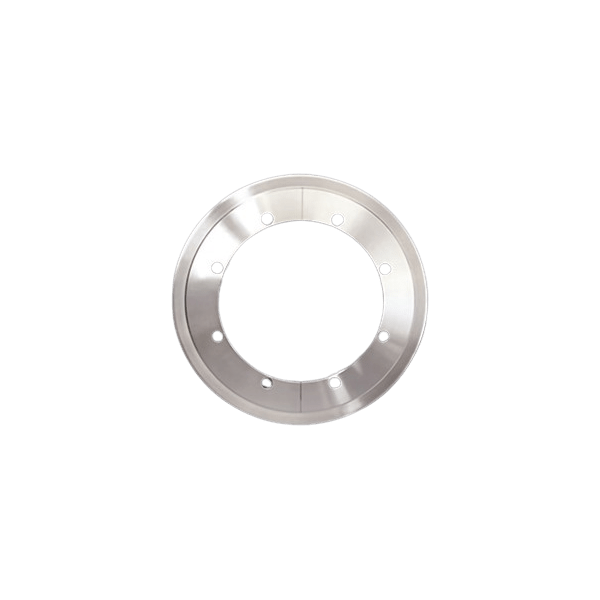

High hardness material, wear-resistant and durable Precise manufacturing process to ensure cutting quality Efficient drive system for fast rewinding

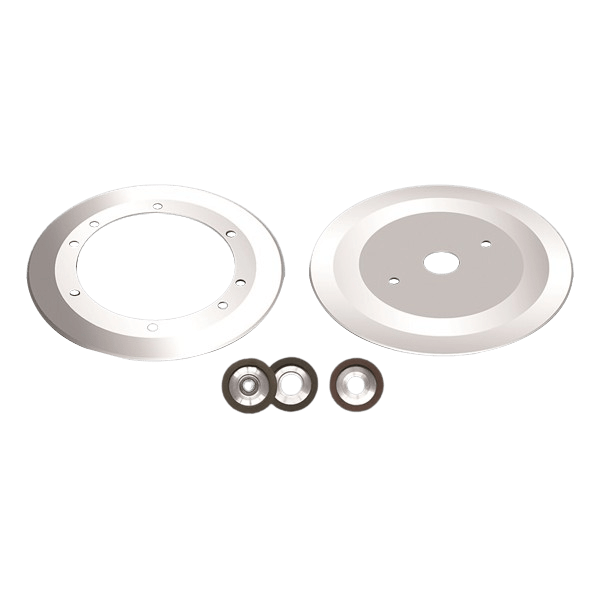

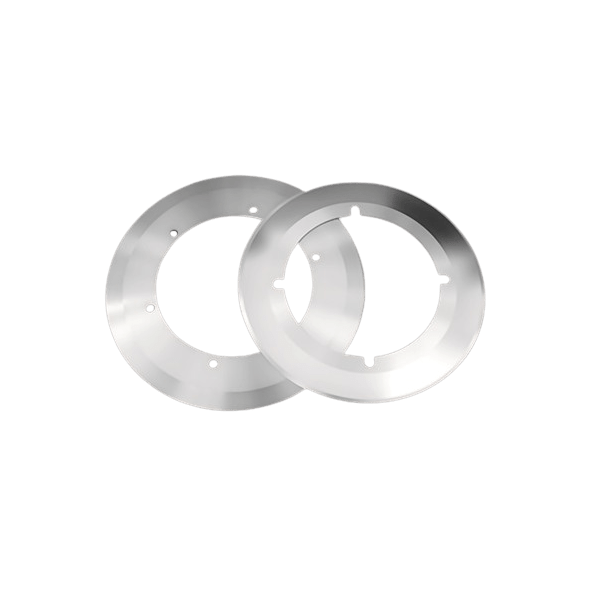

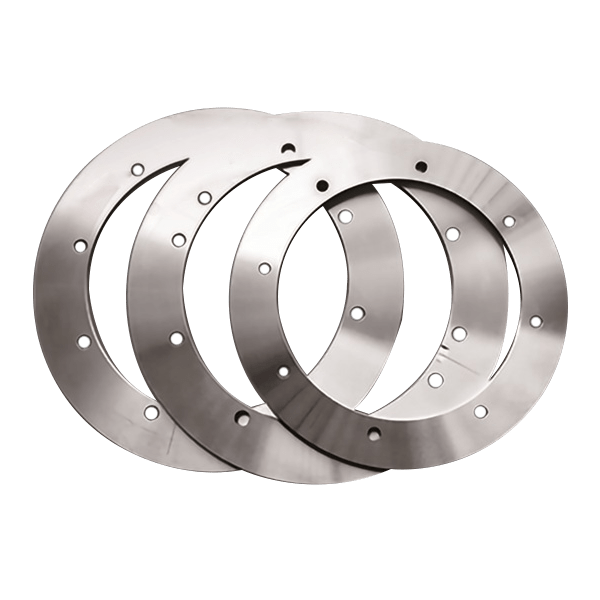

Rotate around the entire cutting edge. Suitable for high-force, large-volume cutting, such as books and thick cardboard. The structure is solid, the design is beautiful, and the cut surface is flat.

This product utilizes advanced materials and precision manufacturing processes to ensure that it demonstrates excellent performance and stability in a variety of application scenarios.

Sharp and durable, with a hardness of HRC58~60, it cuts paper efficiently and improves work efficiency.

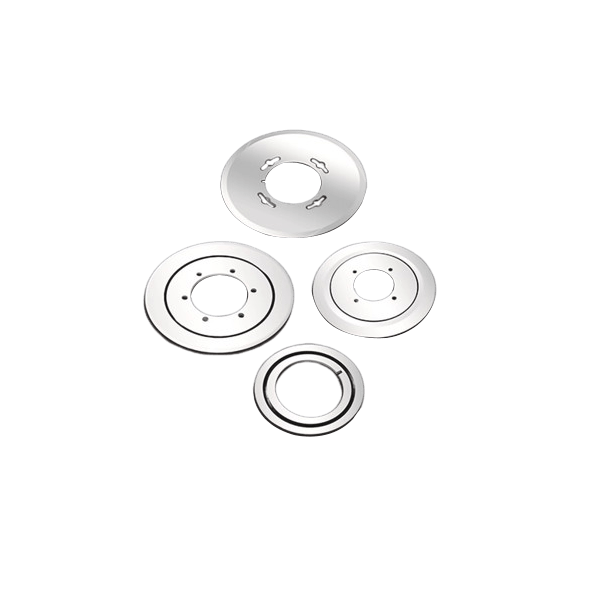

Type: flat round knife, disc knife Material: 9CrSi, D2, etc. Features: sharp cutting, high precision, durability Application: Paper industry, improving paper quality and appearance

Suitable for rewinder blades. High precision and repeatability of slitting settings. Quick response, easy maintenance and modification.