Applications of Rubber Tread Cutters for Enhancing Efficiency

A rubber tread cutter is a specialized machine designed to precision-cut rubber materials, primarily used in tire manufacturing, retreading, and rubber goods production. Its applications span across industries where rubber components require customized shaping, sizing, or recycling. Below, we explore its key uses, benefits, and industrial significance.

Applications of Rubber Tread Cutters: Enhancing Efficiency in Tire and Rubber Processing Industries

1. Tire Manufacturing & Retreading

a. Tread Pattern Creation

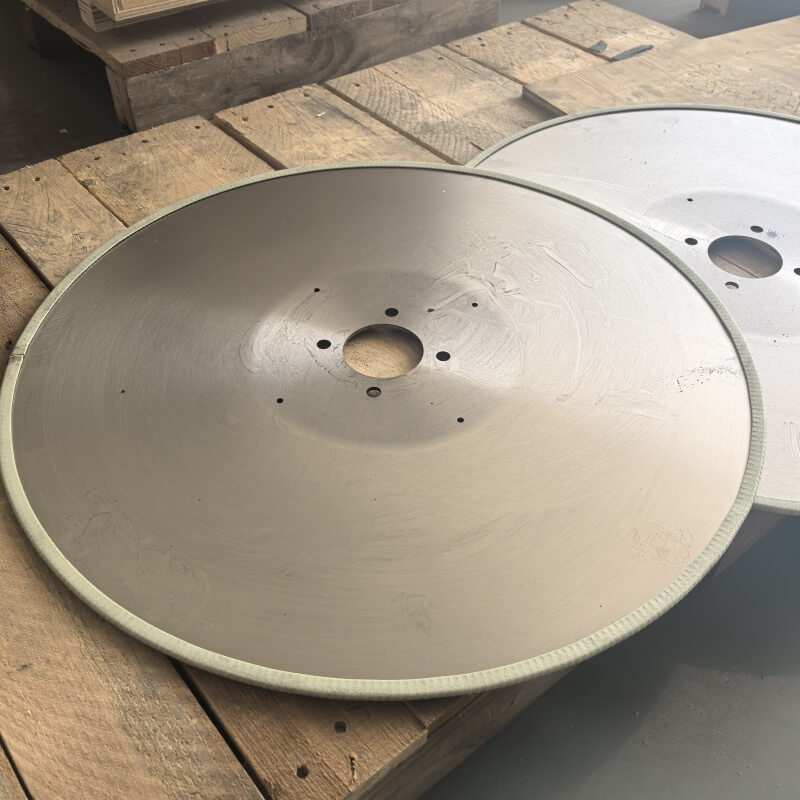

In tire production, tread cutters are indispensable for carving intricate patterns into raw rubber compounds. These patterns determine tire performance, including traction, noise reduction, and wet/dry grip. The machine uses sharp, durable blades or laser systems to cut precise grooves, sipes, and lugs, ensuring consistency across large production runs.

b. Tire Retreading

Retreading extends the lifespan of worn tires by replacing the tread layer. Rubber tread cutters strip off old treads and prepare the casing for new rubber application. They also cut fresh treads to match the tire’s dimensions, reducing waste and lowering costs for fleet operators and consumers.

2. Rubber Recycling & Upcycling

a. Scrap Tire Processing

Every year, billions of tires are discarded globally. Tread cutters play a vital role in recycling by shredding used tires into smaller, uniform pieces. These “crumbs” or “chips” are repurposed into rubber mats, playground surfaces, asphalt modifiers, and even new tire compounds, promoting sustainability.

b. Size Reduction for Reprocessing

For industrial rubber recycling, cutters reduce bulky scrap into manageable sizes, facilitating easier melting, molding, or extrusion. This process minimizes energy consumption in recycling plants and improves the quality of reclaimed rubber.

3. Industrial Rubber Goods Production

a. Custom Gaskets & Seals

Manufacturers of automotive, aerospace, or machinery components use tread cutters to produce rubber gaskets, O-rings, and seals with exact dimensions. The machines ensure tight tolerances, critical for preventing leaks in hydraulic systems, engines, or HVAC units.

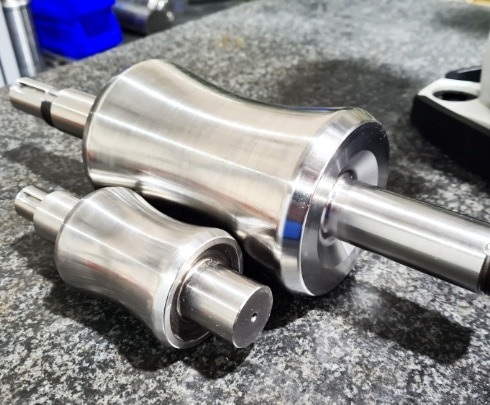

b. Conveyor Belts & Rollers

In material handling, rubber-coated conveyor belts and rollers require precise cutting to fit machinery. Tread cutters trim rubber sheets to the required width and thickness, enhancing durability and reducing friction in logistics and mining operations.

c. Footwear & Sports Equipment

The sports industry relies on tread cutters to shape rubber outsoles for shoes, cleats, and athletic mats. Custom tread designs improve grip, shock absorption, and flexibility, catering to athletes’ needs.

4. Automotive Aftermarket & Customization

a. Off-Road Tire Modifications

Enthusiasts and professionals use tread cutters to customize tires for off-road vehicles, adding deeper lugs or aggressive patterns for mud, snow, or rock terrain. This enhances traction in challenging conditions.

b. Anti-Slip Solutions

Tread cutters create textured rubber overlays for vehicle steps, ramps, or industrial flooring, reducing slip risks in wet or oily environments.

5. Construction & Infrastructure

a. Rubberized Asphalt

Crumb rubber from tire recycling is mixed with asphalt to create quieter, more durable road surfaces. Tread cutters process scrap tires into fine particles suitable for this application, improving road longevity and reducing traffic noise.

b. Bridge Bearings & Expansion Joints

Engineered rubber components in bridges and buildings require precise cutting to absorb vibrations and accommodate thermal expansion. Tread cutters ensure these parts meet structural safety standards.

6. Aerospace & Defense

a. Aircraft Tire Maintenance

Aircraft tires endure extreme conditions, necessitating regular retreading. Tread cutters strip and apply new treads with military-grade precision, ensuring safety during takeoff and landing.

b. Noise-Dampening Materials

Rubber gaskets and liners in aircraft cabins are cut to exact specifications using tread cutters, reducing engine and cabin noise for passenger comfort.

Advantages of Using Rubber Tread Cutters

- Precision: CNC-controlled systems achieve ±0.1mm accuracy, critical for high-performance applications.

- Efficiency: Automated cutting reduces labor costs and production time compared to manual methods.

- Versatility: Handles various rubber types (natural, synthetic, reclaimed) and thicknesses (1mm–50mm+).

- Sustainability: Supports circular economy goals by enabling tire recycling and waste reduction.

Future Trends

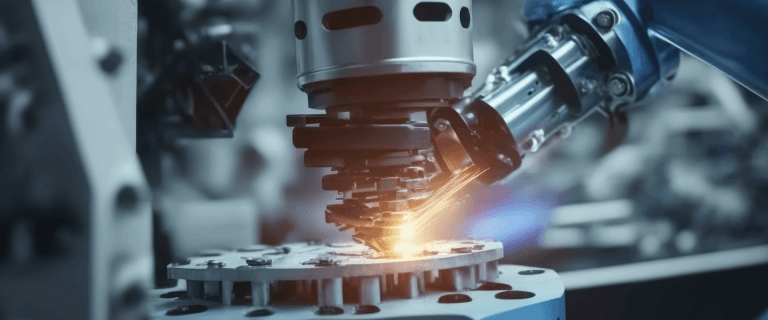

- Laser Cutting Integration: Advances in laser technology offer faster, cleaner cuts without blade wear.

- AI-Powered Optimization: Machine learning algorithms predict blade wear and optimize cutting paths for minimal material waste.

- Portable Units: Smaller, battery-operated cutters for on-site tire repairs in remote locations.

Conclusion

Rubber tread cutters are unsung heroes in industries where rubber meets precision. From ensuring safe, high-performance tires to enabling sustainable recycling practices, these machines drive innovation across manufacturing, construction, and beyond. As technology evolves, their role in reducing waste and improving product quality will only grow, cementing their place as essential tools in modern industry.