High Precision Industrial Blades for Steel Pipe Manufacturers

In the dynamic and competitive landscape of steel pipe manufacturing, the choice of industrial blades is pivotal in determining the efficiency, precision, and overall quality of the production process. Industrial blades play a crucial role in various stages of steel pipe production, from cutting raw materials to finishing the final products. This article delves into the significance of industrial blades in steel pipe manufacturing, highlighting their types, applications, and the benefits they bring to manufacturers.

Types of Industrial Blades in Steel Pipe Manufacturing

1. Circular Saw Blades

Circular saw blades are commonly used in steel pipe manufacturing for cutting large sections of steel into manageable lengths. These blades are typically made from high-speed steel (HSS) or carbide-tipped materials, offering excellent hardness and wear resistance. The circular design allows for smooth and efficient cutting, reducing material waste and improving production speed.

2. Band Saw Blades

Band saw blades are another essential type of industrial blade used in steel pipe production. They are ideal for cutting small to medium-sized pipes and can handle a wide range of materials, including carbon steel, stainless steel, and alloy steels. Band saw blades are known for their flexibility, which enables them to make curved or irregular cuts, providing greater design flexibility in pipe manufacturing.

3. Slitting Knives

Slitting knives are specialized blades used for slitting or cutting narrow strips of steel from larger coils. In steel pipe manufacturing, slitting knives are crucial for preparing the raw material for subsequent forming and welding processes. These blades are designed to ensure precise and clean cuts, minimizing material deformation and improving the overall quality of the slitted strips.

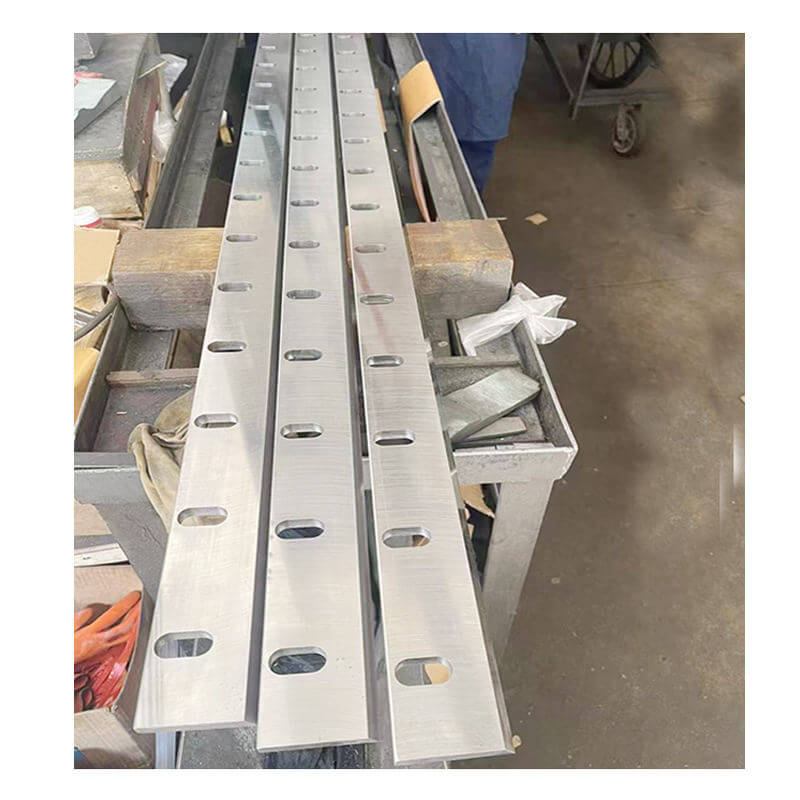

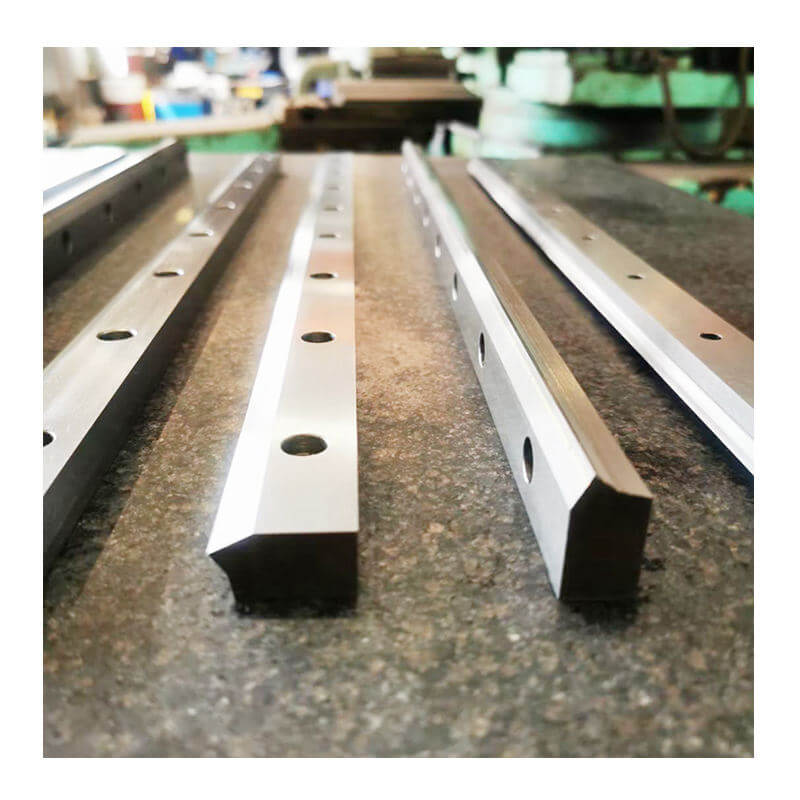

4. Shearing Blades

Shearing blades are used in shearing machines to cut steel sheets or plates into specific shapes and sizes. In steel pipe production, shearing blades are often employed to cut the ends of pipes to the desired length or to trim excess material during the forming process. These blades are characterized by their high cutting force and durability, ensuring accurate and efficient shearing operations.

Applications of Industrial Blades in Steel Pipe Manufacturing

1. Raw Material Cutting

Industrial blades are used to cut raw steel materials, such as billets or coils, into the required lengths for pipe production. This initial cutting stage is critical as it sets the foundation for the entire manufacturing process. Precise cutting ensures that the subsequent forming and welding operations are carried out smoothly, resulting in high-quality steel pipes.

2. Pipe Forming and Welding

During the forming and welding stages, industrial blades are used to trim excess material, cut pipes to specific lengths, and prepare the pipe ends for welding. For example, circular saw blades can be used to cut the formed pipes to the desired length, while shearing blades can trim the pipe ends to ensure a proper fit during welding.

3. Pipe Finishing

In the finishing stage, industrial blades are used for various tasks, such as deburring, chamfering, and cutting grooves on the pipe surfaces. These operations improve the appearance and functionality of the steel pipes, making them suitable for various applications in industries such as construction, oil and gas, and automotive.

Benefits of Using High-Quality Industrial Blades

1. Improved Efficiency

High-quality industrial blades are designed to cut through steel materials quickly and efficiently, reducing production time and increasing overall productivity. Their sharp edges and durable construction ensure consistent cutting performance, minimizing downtime for blade changes and maintenance.

2. Enhanced Precision

Precision is essential in steel pipe manufacturing to meet strict quality standards and customer requirements. Industrial blades with precise cutting edges and advanced designs can achieve accurate and consistent cuts, resulting in pipes with uniform dimensions and smooth surfaces.

3. Cost Savings

While high-quality industrial blades may have a higher initial cost, they offer long-term cost savings through reduced material waste, lower maintenance requirements, and extended blade life. Investing in the right blades can lead to significant savings in the long run, improving the profitability of steel pipe manufacturing operations.

In conclusion, industrial blades are indispensable tools in steel pipe manufacturing, playing a vital role in ensuring efficiency, precision, and quality. By selecting the right types of blades and maintaining them properly, manufacturers can optimize their production processes, meet customer demands, and stay competitive in the market. As technology continues to advance, we can expect to see further innovations in industrial blade design and manufacturing, further enhancing the capabilities of steel pipe manufacturers. Loacted in China, Nanjing Shengyuan Machinery Technology Co., Ltd offers customers flexibility by providing customizable options such as size and thickness, catering to their unique preferences and requirements. This ensures that the product meets their specific needs and requirements. If you are looking for high-quality industrial blades please let us know.