Commissioning Methods for Roller Straightening Machine

Straightening machine is a commonly used equipment in industrial production, used to correct the bending deformation of metal materials. In order to ensure the normal operation of the straightening machine and straightening effect, the operator needs to follow certain adjustments to the operating procedures. Roller straightening machine commissioning method usually includes the following steps

1. Check the equipment:

First of all, check whether all the parts of the roller straightening machine are complete, and make sure that it is installed correctly.

Check whether the power supply, oil circuit is connected normally, and whether the control system works normally.

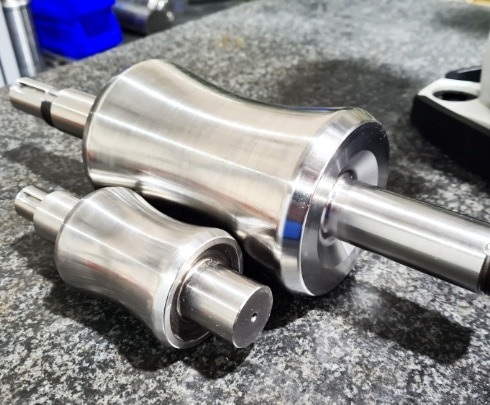

2. Adjust the roller position:

adjust the roller position is one of the key steps in the debugging of roller straightening machine. According to the size and shape of the workpiece, reasonable arrangement of roller spacing and angle. Adjustment of roller position should ensure that the workpiece can be uniform force, so as to achieve the effect of straightening!

3. Adjust the roller pressure:

according to the material and shape of the workpiece, adjust the roller pressure. The size of the roll pressure is related to the size of the workpiece, material and straightening requirements. Too little pressure may not be able to achieve the straightening effect, while too much pressure may lead to workpiece damage.

4. Adjust the conveying speed:

The conveying speed of the roller straightening machine is also one of the parameters to be debugged. According to the size and material of the workpiece, adjust the conveying speed to ensure that the workpiece stays between the rollers long enough to achieve the straightening effect.

5. Observe the straightening effect:

In the debugging process, observe the straightening effect of the workpiece, if it does not meet the requirements, you can adjust the roller position, roller pressure or conveying speed until it reaches the desired goal.

6. Debugging control system:

Roller straightening machine is usually equipped with a control system, used to adjust the roller position, roller pressure, conveying speed and other parameters. In the debugging process, it is necessary to ensure that the control system works normally and can accurately control the parameters.

In short, the debugging method of roller straightening machine mainly includes checking the equipment, adjusting the roller position and pressure, adjusting the conveying speed, observing the straightening effect and debugging the control system and other steps. Through gradual debugging, to ensure that the equipment works properly, to achieve the expected straightening effect. Please feel free to contact Shengyuan Machinery if you have any questions about the commissioning method of the roll straightening machine.