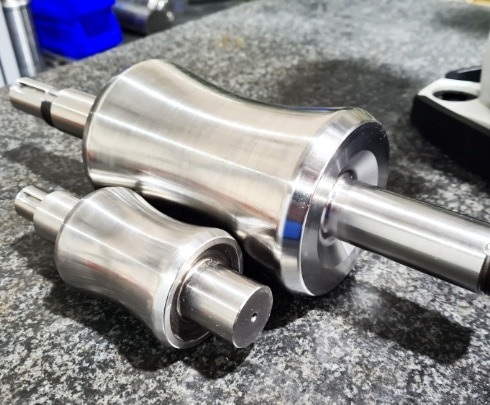

How to Choose the Right Straightening Roller Supplier

Selecting the right straightening roller supplier is critical for achieving optimal performance and quality. Here are some factors to consider:

1. **Experience and Expertise**

Look for suppliers with extensive experience in manufacturing straightening rollers. Their expertise will ensure that they understand the intricacies involved in producing high-quality custom rollers.

2. **Customization Capabilities**

Ensure that the supplier offers comprehensive customization options. This includes the ability to change dimensions, materials, and designs according to your specific needs.

3. **Quality Assurance**

Check if the supplier follows strict quality control measures. Certifications like ISO can indicate a commitment to maintaining high standards.

4. **Customer Support**

Good customer service is essential. A reliable supplier should provide support throughout the purchasing process and after-sales services to address any concerns or issues you may encounter.

5. **Pricing Structure**

While pricing shouldn’t be the sole determining factor, it’s essential to compare costs among different suppliers. Look for transparent pricing structures with no hidden fees.

6. **Reviews and Testimonials**

Research reviews and testimonials from previous customers to gauge the reliability and performance of the supplier’s products.

Frequently Asked Questions (FAQs)

Q1: What materials can custom straightening rollers work with?

Custom straightening rollers can be designed to work with a variety of materials, including metals (like steel, aluminum, and copper), plastics, and composites. The material compatibility will often depend on the specific design and application requirements.

Q2: How do I know if I need a custom straightening roller?

If your production process involves materials that require precise shaping or if you have encountered consistent issues with defects, investing in a custom straightening roller could be beneficial. Consulting with a supplier can help determine the best solution for your needs.

Q3: What is the lead time for custom straightening rollers?

Lead time varies based on the complexity of the design and the supplier’s workload. Generally, it can range from a few weeks to several months. Always ask for an estimated timeline before placing your order.

Q4: Can I get a prototype before finalizing my order?

Many reputable suppliers offer the option to create prototypes or samples of custom straightening rollers. This allows you to test the product before committing to a larger order.

Q5: What maintenance do custom straightening rollers require?

Regular maintenance is crucial to prolonging the lifespan of straightening rollers. This typically includes cleaning, lubrication, and inspecting for wear and tear. Your supplier should provide guidelines on maintenance practices specific to their products.

Q6: Are custom straightening rollers more expensive than standard rollers?

While custom straightening rollers may come with a higher initial cost due to their tailored features, the long-term benefits in terms of quality and efficiency can offset this expense. It is essential to evaluate the return on investment based on your specific production needs.

Conclusion

Choosing the right straightening roller supplier like Nanjing Shengyuan Machinery Technology Co., Ltd. is critical for optimizing your manufacturing processes. By investing in custom straightening rollers, you can achieve greater precision, increased productivity, and improved overall quality. As you embark on this journey, keep the tips mentioned above in mind to select a supplier that aligns with your business goals.